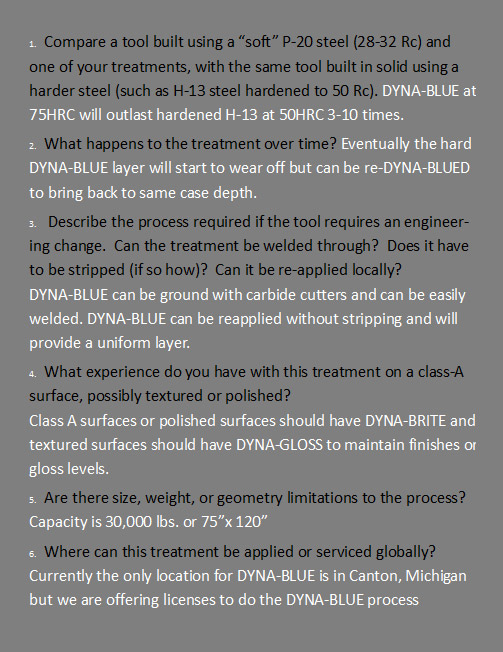

As the industry continues to add fiberglass to strengthen the molded parts, the increase in mold wear has expanded the need for DYNA-BLUE to reduce wear, downtime and operating costs!!!” DYNA-BLUE has increased Tool Life by up to 10 times while adding lubricity and anti-sticking properties. Class A surfaces or polished surfaces should have DYNA-BRITE and textured surfaces should have DYNA-GLOSS to maintain finishes or gloss levels. Many companies have made DYNA-BLUE their Global Standard or Benchmark!!!

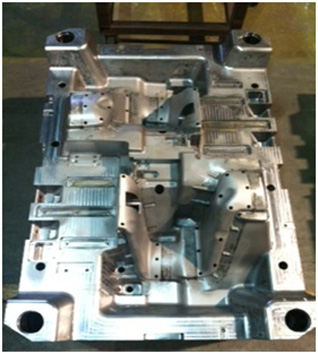

Plastic Injection Molds, Cavities, Cores, Inserts, Lifters, Slides, Guides, Ejector pins, Feedscrews

Benefits of DYNA-BLUE®

- 75+ HRC Surface resists wear from glass filled plastic 2-10 times longer than ion nitriding/chrome plating. (Click here to see a microstructure comparison of DYNA-BLUE vs Nitride)

- Corrosion resistance: resists attack from PVC, Acetic Acid, Citric Acid, Salt water (Click here for test results)

- Increased release properties & lubricity-reduces coefficient of friction

- Reduces parting line erosion from glass filled plastics

- Anti-galling & anti-sticking properties.

- Maintains excellent micro finishes

- No flaking since DYNA-BLUE® is a diffusion process and not a coating.

- Capacity 75”x120” – up to 30,000 lbs.

- Growth of .0001”- .0002” per side.

- Will not soften even at elevated temperatures.

- High surface hardness, Hrc 75+ no brittleness

- Enhanced die repair and weldability (Click here for testimonial)

- Overnight service available

Testimonial

LDM Technologies, Port Huron, Michigan has identified DYNA-BLUE® as “Best Practice” for the following reasons:

1- Reduced monthly tooling budget from $70,000 to $6,000

2- Eliminated deburring knives throughout the plant and also safety related issues as flash has been eliminated (sharp parting lines=no flash).

3- Part component PPM from 36+ to single digit.

4- Ran one die using polypropylene with 30% glass, 2,000,000 plus cycles. Customer wanted to make an engineering change and was willing to pay $360,000 for new tooling. A new die was not required.

LDM saved Ford $360,000.00

Download Brochure