DYNA-BLUE® & DYNA-BLUE PLUS™: “Eco-friendly new processes that are revolutionizing the Surface Treating Industry. Many companies across the world are specifying DYNA-BLUE® as their Global Standards and Benchmarks for increasing Tool Life. DYNA-BLUE® is a Leading Edge Innovation with Exceptional results.”

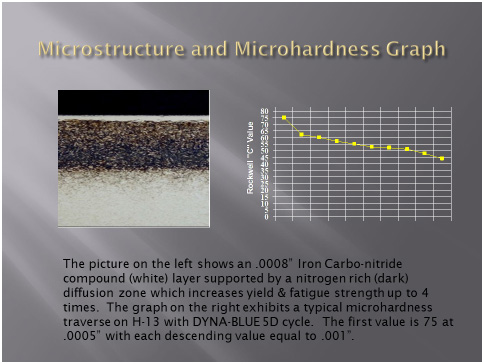

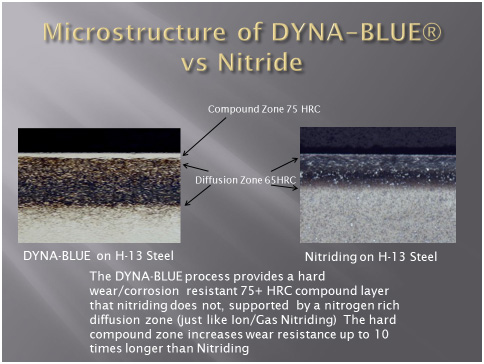

DYNA-BLUE® is a low temperature Ferritic Nitrocarburizing surface treatment with 20+ engineered variations typically 950°-1060°F. The process is generally referred to as “Ferritic Nitrocarburizing” and it yields two, distinct metallurgical characteristics: 1. Compound layer of 1880 Vickers (75+ Rockwell C) .0005”-.002” (depends on application). 2. Nitrogen enriched diffusion zone, .002 - .010" deep to support the compound zone (depends on application). This process penetrates holes, bores and ribs as it is not a line of sight process like Nitriding or PVD Coatings The metallurgical properties are diffused into the base material, therefore, therefore it will not flake, peel or chip off like a coating.

WHAT ARE THE BENEFITS OF DYNA-BLUE®?

- High wear resistance- surface hardness, typically greater than Rockwell “C” 75. (Click here for microhardness graph)

- High corrosion resistance: 168+ Salt Spray hours when combined with our NITROWEAR Dip/Spray (Click here for test results)

- High levels of Residual Compressive Stress to resist heat checking, fatigue and cracking. (Click here for test results)

- Lower co-efficient of friction, as low as .03. (Click here for test results)

- Low dimensional variation: .0001"-.0002 growth per side.

- Anti-galling & anti-sticking properties.

- Enhanced release properties and parting line durability on plastic injection molds. (Click here for testimonial)

- Resists soldering, heat checking, and washout on die cast dies. (Click here for testimonial)

- Resists wear from glass filled plastics up to 10 times longer than nitriding or chrome.

- Maintains excellent micro finish.

- Not limited by component geometry or line of sight.

- 100% environmentally friendly.

- Better weldability than traditional nitriding or ion nitriding. (Click here for testimonial)

- Capacity 42"x 134" and 75"x 120", up to 30,000 lbs.

- Hard surface hardness maintains ductility, durability testing has shown that DYNA-BLUE® can bend up to 90° without cracking.

- Overnight service is available

Download Brochure

DYNA-BLUE® (FERRITIC NITROCARBURIZING) MICROSTRUCTURE

The microstructure of a Ferritic Nitrocarburized treated sample consists of a hard (75+ HRC) compound zone of carbon and nitrogen with a nitrogen rich diffusion zone beneath for support. The hard compound layer increases wear and corrosion resistance, has high compressive residual stress to resist wear, heat checking and cracking. When combined with an oxide layer on the surface it prevents atomic bonding of aluminum, plastic, etc. and reduces the coefficient of friction.