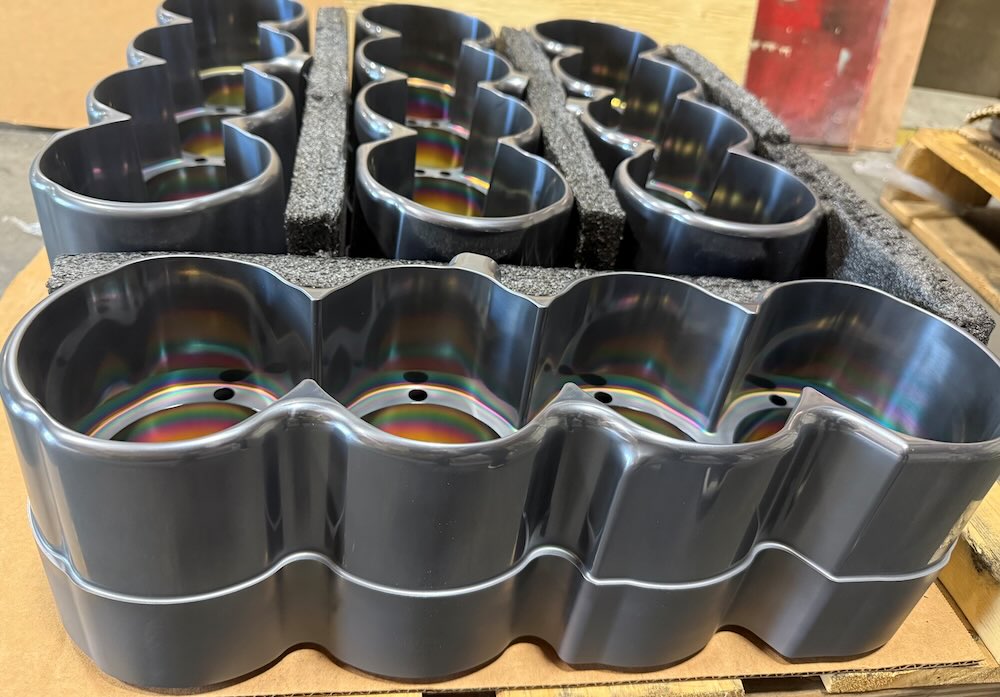

DYNA-MAX™

The Ultimate Dual-Layer Defense for Wear Applications

DYNA-MAX™ combines a hard DYNA-BLUE® support layer with the ultra-hard surface finish of PVD coatings—providing unmatched resistance to wear soldering, washout, and thermal fatigue in aggressive, high-wear environments.

What Is DYNA-MAX™?

DYNA-MAX™ combines the internal strength of DYNA-BLUE® with the surface hardness and lubricity of PVD coatings. Ideal for extreme environments.

DYNA-MAX™ is a cutting-edge duplex coating system that fuses two powerful technologies:

- A diffused DYNA-BLUE® base layer (75+ HRC) provides internal hardness and structural fatigue resistance.

- A 5–8 micron PVD topcoat (such as CrWN, TiN, TiAlN, or CrN) adds an ultra-hard, low-friction surface ideal for aggressive casting and stamping conditions.

This layered approach solves a major industry pain point: when PVD coatings wear off, tool life typically collapses. With DYNA-MAX™, even if the topcoat is gone, the base DYNA-BLUE® treatment continues to protect your tool.

How DYNA-MAX™ Compares

This technology is especially effective for tools exposed to extreme wear and caustic environments, where traditional coatings quickly fail due to wear soldering and erosion. DYNA-MAX™ resists the dreaded “egg shell effect” and galling often seen in high-pressure die cast or forming operations—preserving edge integrity even at end gates.

| Feature | PVD Coating Only | DYNA-BLUE® Only | DYNA-MAX™ |

|---|---|---|---|

| Surface Hardness | 72–75 HRC | 75+ HRC | 80+ combined |

| Thermal Fatigue Resistance | Low | High | Extreme |

| Soldering Resistance | Moderate | High | Maximum |

| Post-Coating Tool Life | Sharp drop-off | Maintained | Extended |

| Best For | Surface wear only | Internal fatigue | High-temp + multi-force environments |

Designed for Peak Tooling Performance in Harsh Environments

DYNA-MAX™ Key Benefits

DYNA-MAX™ is built for tools under fire:

-

Die Casting: Structural aluminum and high-silicon alloys

-

Hot Forming & Stamping Dies: End gate and thin-wall parting lines

-

Extrusion Dies: Heavy-duty press and die resistance

-

Aerospace Components: Lightweight alloys with high cycle rates

-

Automotive EV Programs: Aluminum battery casings and enclosures

- Maximum resistance to soldering, erosion, heat checking, and washout

- Enhanced surface hardness and lubricity from PVD coatings

- 2-in-1 system maintains performance even if the topcoat wears away

- Deeper thermal fatigue protection via DYNA-BLUE® base

- Prevents “egg shell” effect and erosion at gate areas

- Increases part quality and reduces maintenance

- Ideal for die cast, extrusion, hot stamping, and high-temp forming tools

- Supports coatings: TiN, TiAlN, CrN, CrWN

- Capacity: 39” x 55” or up to 2,000 lbs

- ISO 9001:2015 certified processes

Simple and Efficient Treatment Process

Working with Dynamic is straightforward. We’ve streamlined the entire process to deliver exceptional results with minimal disruption:

Consultation

We listen to your specific tooling challenges and performance goals.

Data Collection

We inspect the steel type, current failure modes, and customer requirements.

Process Design & Application

We apply the optimal DYNA-BLUE® and PVD Coating process, tailored to your material, objectives, and application.

Quality Assurance

Every part is tested and inspected to ensure performance specs are met or exceeded.

When you need the maximum tool life you need DYNA-MAX

I have experienced 4x life of my tooling in very aggressive applications with DYNA-MAX.

Ready to Maximize Your Tool Life?

DYNA-MAX™ is more than a coating—it’s a high-performance defense system for your tooling. When the job is demanding, and failure isn’t an option, let’s build a solution that lasts.