DYNA-BRITE™

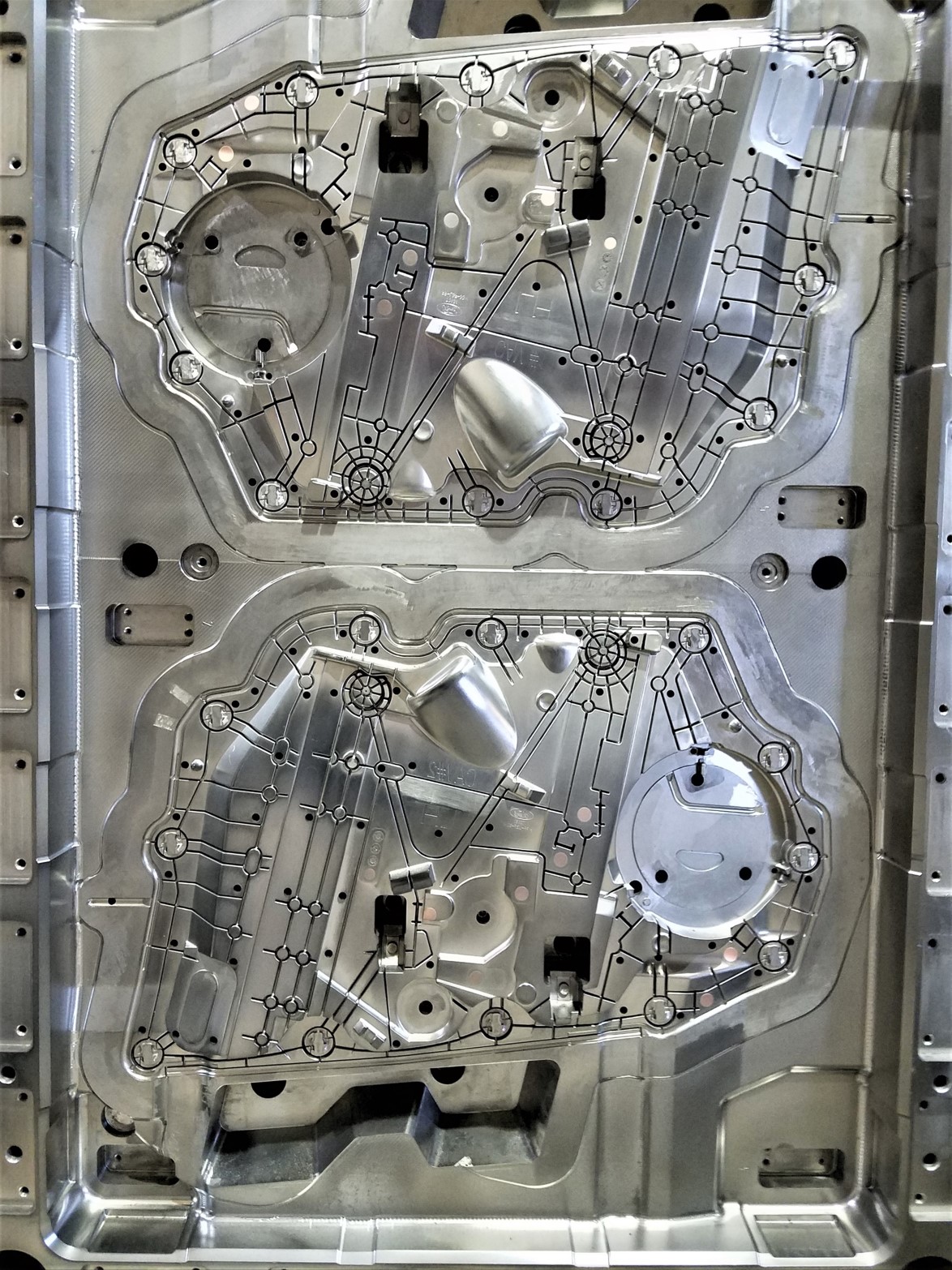

Maintain Gloss Levels. No More Endless Re-Texturing Your Injection Mold Due To Wear From High Glass Content.

DYNA-BRITE™ is a specialty surface treatment to prevent wear form glass filled plastics, PVC and caustic materials-extending the life of your mold dramatically.

What Is DYNA-BRITE™?

DYNA-BRTE is a cost-effective solution with 2-10 times better tool life than nitriding, chrome, nickel, or PVD coatings.

DYNA-BRITE™ is a proprietary process designed to provide a 75+ HRC surface to resist wear and provide better release, while maintaining surface finish on tools with high polish and gloss levels on textured tools. It’s specifically designed for tools with glass contents up to 60%.

DYNA-BRITE penetrates deep holes and ribs and is not line of sight like nitriding, chrome or nickel coatings. Even water lines are provided improved corrosion resistance.

DYNA-BRITE makes engineering changes easier and is weldable without stripping.

DYNA-BRITE™ vs. Traditional Finishes

| Feature | DYNA-BRITE™ | Chrome Plating | Ion/Gas Nitriding |

|---|---|---|---|

| Surface Hardness | 75+ HRC | 63-70 HRC | 60–65 HRC |

| Surface Clarity | Maintains Surface Finish | possible | Matte or grey |

| Edge Build-Up | ❌ None | ✅ Common | ❌ None but brittle |

| Weldability | ✅ Excellent | ❌ Poor | ❌ Pin hole porosity |

| Geometry Limitations | ❌ None | ✅ Line-of-sight | ✅ Limited access |

| Flaking/Peeling | ❌ None | ✅ Common | ❌ Edges may be brittle |

Engineered for Precision, Built to Shine

DYNA-BRITE™ Key Benefits

-

Longer Tool Life: 75+ HRC Surface resists wear from glass filled plastics

-

Corrosion resistance: resists attack from PVC, Acetic Acid, protects water lines from corrosion & buildup

-

Improved release properties & lubricity-reduces coefficient of friction

-

No flaking or peeling since the process is a diffusion process and not a coating.

-

Growth of .0001”- .0002” per side.

-

Makes engineering changes easier and is weldable. Can be removed (stripped) if needed with a diffusion process.

-

Low temperature process to avoid size change.

-

Overnight service available on tools up to 7,000 lbs.

-

Capacity: up to 77″ x 110″, or 30,000 lbs

DYNA-BRITE™ is ideal when you need:

-

Maximum wear resistance that holds up over millions of cycles

-

Maximum corrosion resistance from caustic plastics, rubber, or PVC

-

Reduced tool maintenance and downtime

-

A mold that has high polish, texture, or needs better release

-

Confidence in repairability and easy engineering changes.

-

A process that is cost-effective

-

Fast turnaround

Simple and Efficient Treatment Process

Working with Dynamic is straightforward. We’ve streamlined the entire process to deliver exceptional results with minimal disruption:

Consultation

We listen to your specific tooling challenges and performance goals.

Data Collection

We inspect the steel type, current failure modes, and customer requirements.

Process Design & Application

We apply the optimal DYNA-BRITE process, tailored to your material, objectives, and application.

Quality Assurance

Every part is tested and inspected to ensure performance specs are met or exceeded.

What our customers saying

“Heartfelt Thank You! As we celebrate our 25th anniversary, we want to take a moment to express our sincere gratitude for the vital role you’ve played in our journey. Reaching this milestone would not have been possible without the strong partnerships and reliable support of valued suppliers like you. Over the past two and a half decades, your commitment to quality, consistency, and service has helped us grow and deliver on our promises to our own customers. Whether during times of steady growth or periods of unexpected challenge, your team has stood by us with professionalism, flexibility, and dedication. For that, we are truly thankful. We deeply appreciate your continued partnership and look forward to building on this strong foundation in the years to come. Here’s to everything we’ve accomplished together—and all that lies ahead!

Our IP tool has produced over 2 million parts and is still running thanks to DYNA-BRITE

Ready to Protect Your Mold—and Your Surface Finish?

DYNA-BRITE™ protects high glass content, caustic plastics or PVC against corrosion, resin off-gassing, poor venting, and other factors that degrade traditional mold finishes.

If you’re tired of excessive maintenance and downtime or inconsistent mold finishes, DYNA-BRITE™ gives you a long-lasting edge.

Better part quality. Fewer rejections. Dramatically longer tool life.