DYNA-BLUE PLUS™

Give Your Tooling a Second Life.

And a Longer One.

When standard nitriding or PVD coatings wear out too quickly, DYNA-BLUE PLUS™ is your answer with a deeper, more resilient surface treatment that enhances finish, combats wear soldering, and resists fatigue—proven to last 2–10x longer in even the harshest die casting environments.

What Is DYNA-BLUE PLUS™?

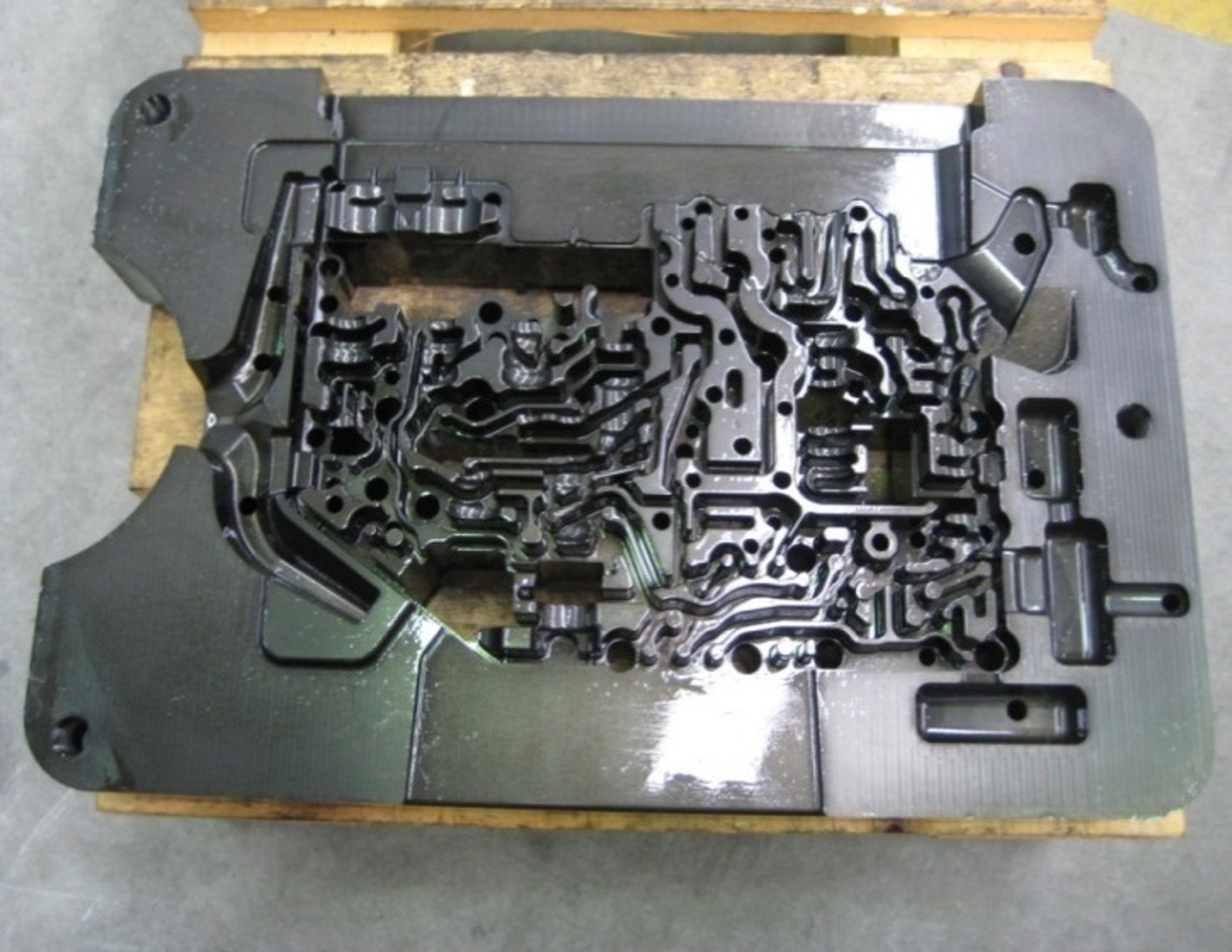

Enhanced surface finish for better release and material flow with longer tool life, even on used tools.

DYNA-BLUE PLUS™ is a powerful surface treatment that combines low-temperature Ferritic Nitrocarburizing (950–1050°F) with a proprietary surface enhancement designed to boost durability, improve material flow, and tool life to used tools.

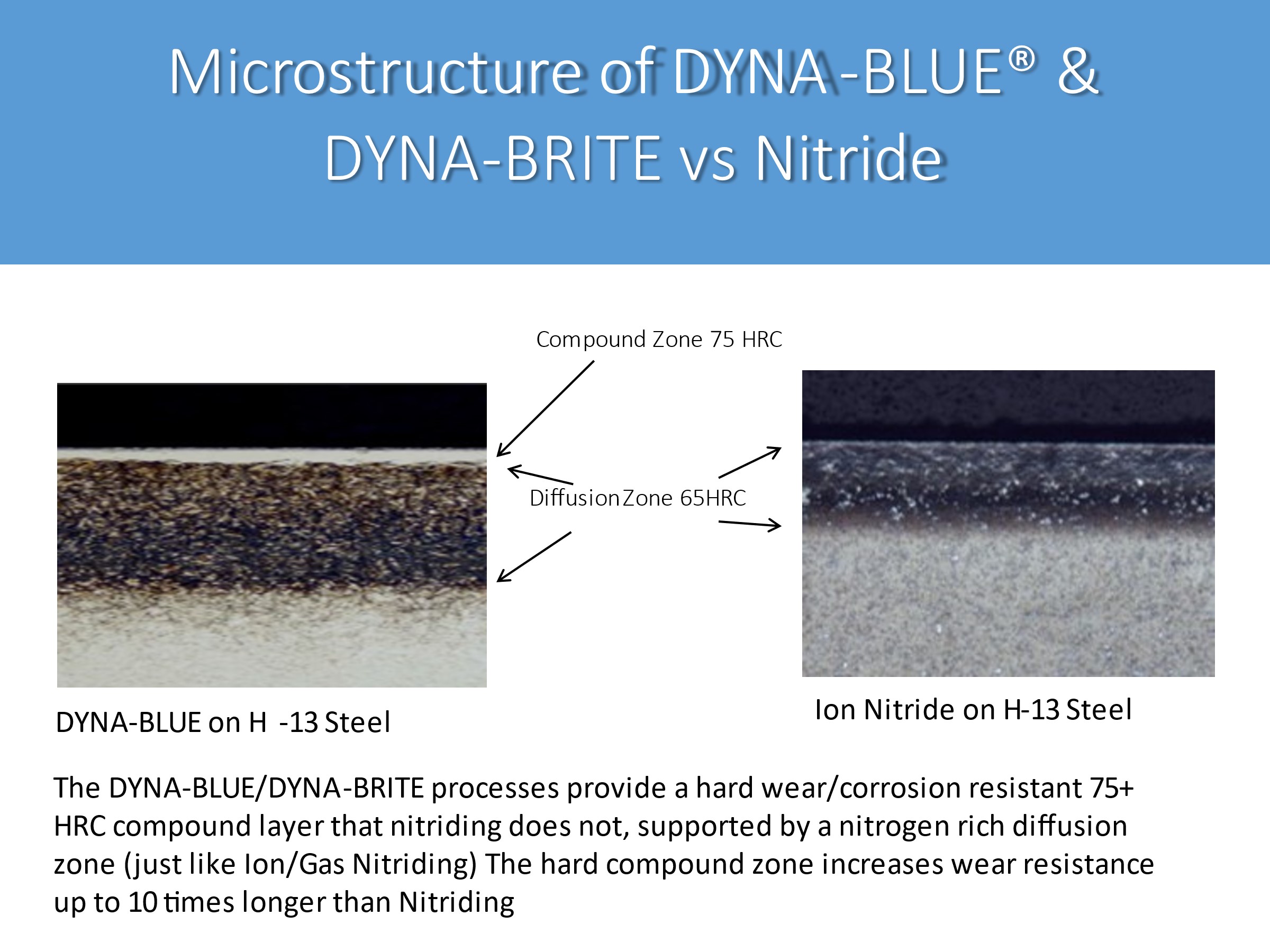

This dual-action process forms a 75+ HRC compound layer and a nitrogen-rich diffusion zone deep into the steel—creating a wear-resistant surface with increased life, resists soldering and erosion, and enhances part release.

It’s particularly effective in aluminum magnesium die casting and forging tools—where soldering, erosion, and heat checking are everyday battles.

How It Works

DYNA-BLUE PLUS™ improves wear resistance, surface finish, and resists soldering and erosion even with high-silicon aluminum alloys. It can be reapplied and is ideal for reconditioning used tools.

DYNA-BLUE PLUS™ vs. Other Treatments

| Feature | DYNA-BLUE PLUS™ | Ion/Gas Nitriding | Hard Chrome or Nickel Coatings |

|---|---|---|---|

| Surface Hardness | 75+ HRC | ~60–65 HRC | 63–70 HRC |

| Soldering Resistance | High | Moderate | Moderate |

| Thermal Fatigue Strength | Excellent | Moderate | Low |

| Friction Coefficient | 0.03 – 0.10 | 0.35–0.45 | 0.15 – 0.25 |

| Reusability on Old Dies | ✅ | ❌ | ❌ |

| Line-of-Sight Limitation | ❌ | ✅ | ✅ |

| Environmental Safety | ✅ | ✅ | ❌ |

Proven Performance in the Most Demanding Die Casting & Forging Environments

Key Benefits of DYNA-BLUE PLUS™

DYNA-BLUE PLUS™ is engineered for:

-

Die Casting Dies: used or previously nitrided or DYNA-BLUE processed

-

Forging Dies: needing better release and better wear resistance

-

Die-Casting Aluminum Alloys: Especially Silifont™, Aural™, and Mercalloy™

-

Used Tooling: Rejuvenate high-wear dies and extend their useful life

-

Defense & Automotive: Certified Tier 1 supplier to mission-critical programs

-

Resists wear, heat checking, soldering, and erosion—even with aggressive aluminum alloys

-

Surface hardness up to 75+ Rockwell “C” (1880 Vickers)

-

2–10x longer tool life vs. gas/ion/salt bath nitriding or PVD coatings

-

Resists aluminum, magnesium, and zinc alloy attack

-

Low dimensional variation: only .0001”–.0002” per side

-

Residual compressive stress improves fatigue strength

-

Coefficient of friction as low as 0.03

-

Better material flow and release properties

-

Excellent weldability—better than ion/gas nitriding

-

No line-of-sight limitations—treats holes, ribs, and complex geometries

-

Environmentally friendly and ISO 9001:2015 certified

-

Military specs compliant: AMS 2757B and 2750E

-

Available in sizes up to 77” x 100” and up to 30,000 lbs

-

Can rejuvenate and extend life of used dies

Simple and Efficient Treatment Process

Working with Dynamic is straightforward. We’ve streamlined the entire process to deliver exceptional results with minimal disruption:

Consultation

We listen to your specific tooling challenges and performance goals.

Data Collection

We inspect the steel type, current failure modes, and customer requirements.

Process Design & Application

We apply the optimal DYNA-BLUE® process, tailored to your material, objectives, and application.

Quality Assurance

Every part is tested and inspected to ensure performance specs are met or exceeded.

We make a difference on the production floor.

Just ask our customers.

“DYNA-BLUE PLUS™ rejuvenated our used dies and eliminated soldering at critical gate areas. It really saved our production schedule.”

“This is the only process I trust on our legacy tools. We reapply as part of routine maintenance—it’s cost-effective and keeps us running.”

Let’s Maximize the Life of Your Tooling

DYNA-BLUE PLUS™ isn’t just a coating—it’s an engineering solution that improves finish, performance, and reliability. Whether you’re fighting soldering, erosion, or wear, we’ll help you select the right process to solve it.