DYNA-BLUE®

The Toughest Surface You’ll Never See

Engineered to protect your most valuable tooling, DYNA-BLUE® offers unmatched wear resistance, heat fatigue strength, and corrosion protection—without the drawbacks of traditional coatings.

What Is DYNA-BLUE®?

Advanced surface treatments that protect steel tools from wear, corrosion, and fatigue.

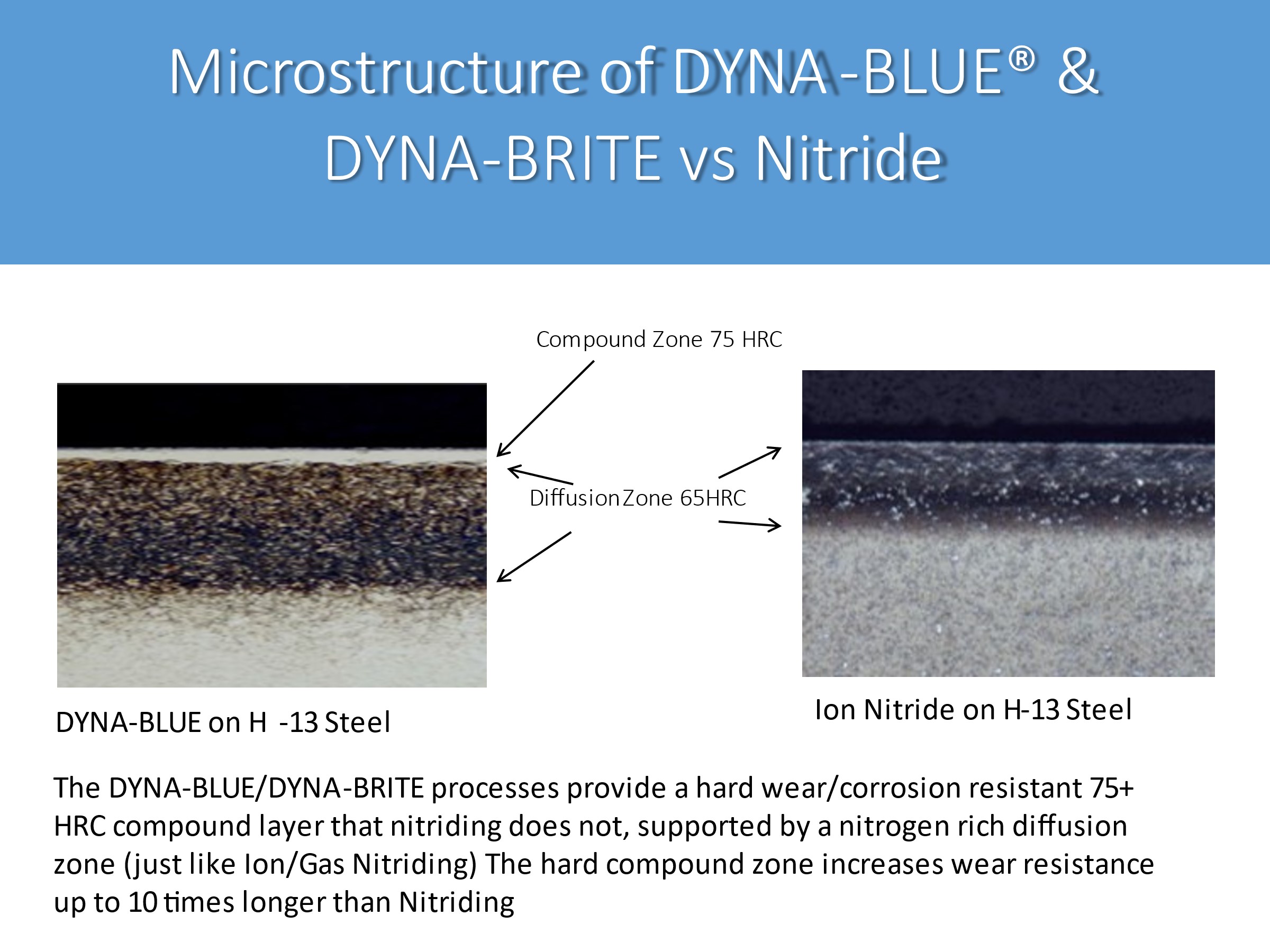

DYNA-BLUE® is a low-temperature ferritic nitrocarburizing treatment designed to create an ultra-hard, corrosion-resistant surface on steel tools and components. Using a proprietary process with over 250 custom-engineered variations, DYNA-BLUE® develops two key layers into the steel itself:

-

A hard compound zone (typically 75+ Rockwell C) for superior wear resistance

-

A nitrogen-enriched diffusion zone for added fatigue and crack resistance

Unlike traditional coatings, DYNA-BLUE® diffuses into the steel—so it won’t flake, chip, or peel. It penetrates internal features, holes, and ribs that line-of-sight methods like chrome, nickel-plating or PVD simply can’t.

How It Works

Each DYNA-BLUE® application is engineered to your steel type and application. Surface hardness, case depth, and cycle times are adjusted to achieve the designed outcome.

DYNA-BLUE® vs. Traditional Coatings

| Feature | DYNA-BLUE® | Ion/Gas/Salt Bath/Nitrading | Chrome Plating |

|---|---|---|---|

| Surface Hardness | 75+ HRC | 60–65 HRC | 63–70 HRC |

| Wear Resistance and Tool Life | Up to 10x longer | Moderate | Moderate |

| Weldability | Good | Poor | Must be stripped |

| Geometry Limits-holes/ribs | None | Limited | Very limited |

| Corrosion Resistance | Excellent (with NITROWEAR®) | Moderate | Moderate |

| Environmentally Friendly | ✅ | ✅ | ❌ (EPA-regulated) |

When you need the Maximum Performance out of your tooling, you need DYNA-BLUE®

Benefits of DYNA-BLUE®

DYNA-BLUE® is trusted by engineers in:

-

Injection Molding: Improves tool life dramatically even on 50% glass filled plastics, over 1-2 million shots.

-

Die Casting: 4-5x tool life, withstands thermal cycling, erosion, and soldering

- Forging: Hammer, press cross roll forge dies 4-5x tool life.

-

Oil & Gas Exploration: Extends life of fluid ends, pumps, plungers 2-10x.

-

Hot forming: resists softening, heat checking & erosion 4-5x.

-

Hot and Cold Stamping: low temperature process for steels like A-2, D-2, S-7. Can also be used in combination with PVD .4-5x

-

Ultra-high wear resistance: Surface hardness typically exceeds 75 Rockwell “C”

-

Outstanding corrosion protection: Over 168 hours of salt spray when paired with NITROWEAR®

-

High compressive stress: Reduces cracking, heat checking, and fatigue

-

Low friction surface: Coefficient of friction as low as 0.03

-

Dimensional stability: Minimal growth (.0001”–.0002” per side)

-

Anti-galling & anti-stick properties

-

Enhanced part release

-

Resists soldering and washout in die casting

-

Handles glass-filled plastics up to 10x better than nitriding or chrome

- Even penetrates water lines, providing corrosive protection

- Unlimited by part geometry

-

Environmentally safe—no hazardous waste

-

Improved weldability over ion or gas nitriding

-

Bends up to 90° without cracking

-

Overnight service available

Simple and Efficient Treatment Process

Working with Dynamic is straightforward. We’ve streamlined the entire process to deliver exceptional results with minimal disruption:

Consultation

We listen to your specific tooling challenges and performance goals.

Data Collection

We inspect the steel type, current failure modes, and customer requirements.

Process Design & Application

We apply the optimal DYNA-BLUE® process, tailored to your material, objectives, and application.

Quality Assurance

Every part is tested and inspected to ensure performance specs are met or exceeded.

Let the results speak for themselves

“After trying different processes to improve the longevity of our molds we have found DYNA-BLUE to be the best.

To date we have DYNA-BLUED about 20 molds and are incorporating DYNA-BLUE on all our new molds where erosion will be a concern.”

Injection Mold End User

Ready to Extend Your Tool Life?

Whether you need to fight wear, corrosion, or downtime: DYNA-BLUE® delivers results that outperform coatings and outdated treatments. Let us help you engineer a better, longer-lasting tool.